The overall extended length is 30 studs giving a better extended to retracted length ratio than the original cylinder.

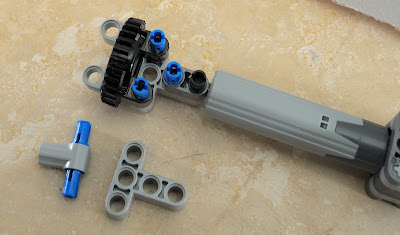

Now the problem to solve is how to go about mounting this. The end that we choose to be the "plunger" end can be connected with a pin or axle as normal, but the "driven" end needs some way to be driven to spin around and handle both pull and push pressure just as the single cylinder's original mounting bracket. Thankfully Lego has a turntable that is just the right size for this.

The cylinder's driven end can be mounted to the geared portion of the turntable so as to be driven by gears or alternately the pictured grey axle connector with the 3L pin can be inserted so that it may be driven by an axle.

Lastly one could do both. That is have an axle and gear drive at the same time. For example one may need to drive a second cylinder from one axle source. Red axle powered by an XL motor drives a cylinder through an axle and the gear at the base of the cylinder drives the cylinder on the other side that lifts the boom.

This joint seems like it should work, but the small gears keep skipping because of the high stress of directly driving two cylinders under high load so this will have to be done in some other way.

Here is the overall view of how these double cylinders are used to mechanize the model's boom, arm, and bucket.