Over the weekend I managed to fully build one shoe and solved some wheel placement problems as well as started to add structural support for the x-brace and body.

I was able to test the shoe and the performance was mediocre. It has lots of torque and does go up and down in gear ratios as needed. Going up an incline seems fine and it is slow as expected.

There is a problem however. On flat ground the shoe lurches, slows down, and lurches again. This is at any motor speed. Best I can tell is that it seems to be that the many dive axles that twist and retain a lot of torsional power like a spring that lets loose once the friction on the drive line is reduced. There is an especially long set of connected axles from the transmission to the sprocket of 17 studs.

This is probably exacerbated by the final output shaft having a 1:1 drive ratio with the drive sprocket and incomplete structural bracing.

I'm going to try a 1:2 gear ratio at the drive shaft.

If that fails I'm thinking I have to redesign the cvt to pass power more directly by gears than by axles. I can't see that being possible, but I haven't tried that yet.

Monday, July 31, 2017

Friday, July 28, 2017

EC750E shoe with cvt, sprocket, and most wheels

After many rebuilds and a poor translation of the cvt design I made to fit in the shoe a design has finally emerged that feels like it works. There are some bracing issue to deal with for the anticipated weight of the whole vehicle.

This is the cvt rebuilt and working nicely with good internal bracing. I left a couple wheels and track pieces for reference to position in the shoe.

This is the view of the shoe from the center of the digger.

This is the view as seen from the outside by viewer. The length is 48 studs which is a tad longer than I would like, but close enough.

This is the cvt rebuilt and working nicely with good internal bracing. I left a couple wheels and track pieces for reference to position in the shoe.

This is the view of the shoe from the center of the digger.

This is the view as seen from the outside by viewer. The length is 48 studs which is a tad longer than I would like, but close enough.

Wednesday, July 26, 2017

Lego mayhem

This is where I make my Lego creations:

This mess is located in the back half of my living room and could use some explanation. My three year old did all of this in one day. In the morning we built a wooden train track, in the afternoon he built a Duplo volcano on the big green Duplo base plate visible in the front with the blue Duplo farm tractor on it. In the evening he explained how everything worked and the mess of a colour layout on the volcano including the red lava. He then proceeded to explode the volcano in a matter of minutes and that is how that massive pile of Duplo ended up on the floor at the back. This was to free the baseplate to make a farm the next day. Mostly you see wooden train track, but you'll also note the Lego city train track around the table and the large blue Rubber Maid bin is full of Duplo train track. We like our trains. Shelves of model trains and other MOCs not shown. The IKEA six bin piece of furniture with the piano on top is full of Duplo pieces. Two more big IKEA bins/drawers hold the 2x2 and 2x4 Duplo bricks respectively. The three tool boxes at the back hold sorted Lego. The toolbox under the table and the one open on the floor holds my sorted technic bricks. The cardboard box under the table holds an orange Jeep 4x4 MOC and all the extra technic tires, rims, and currently most of a spare Volvo loader. This room changes how it looks a lot so I work on the floor. That spot in the middle between the Duplo and the open toolbox is where I was sitting before taking this shot. The big black arm thing to the right and on the floor is the arm of the EC750E MOC I'm currently working on. Hard to see, but a pile of CVT gearboxes for testing is what I was working on at the time.

This mess is located in the back half of my living room and could use some explanation. My three year old did all of this in one day. In the morning we built a wooden train track, in the afternoon he built a Duplo volcano on the big green Duplo base plate visible in the front with the blue Duplo farm tractor on it. In the evening he explained how everything worked and the mess of a colour layout on the volcano including the red lava. He then proceeded to explode the volcano in a matter of minutes and that is how that massive pile of Duplo ended up on the floor at the back. This was to free the baseplate to make a farm the next day. Mostly you see wooden train track, but you'll also note the Lego city train track around the table and the large blue Rubber Maid bin is full of Duplo train track. We like our trains. Shelves of model trains and other MOCs not shown. The IKEA six bin piece of furniture with the piano on top is full of Duplo pieces. Two more big IKEA bins/drawers hold the 2x2 and 2x4 Duplo bricks respectively. The three tool boxes at the back hold sorted Lego. The toolbox under the table and the one open on the floor holds my sorted technic bricks. The cardboard box under the table holds an orange Jeep 4x4 MOC and all the extra technic tires, rims, and currently most of a spare Volvo loader. This room changes how it looks a lot so I work on the floor. That spot in the middle between the Duplo and the open toolbox is where I was sitting before taking this shot. The big black arm thing to the right and on the floor is the arm of the EC750E MOC I'm currently working on. Hard to see, but a pile of CVT gearboxes for testing is what I was working on at the time.

Friday, July 21, 2017

EC750E Two speed automatic CVT shoe drive

The Volvo EC750E has an interesting drive system. It has an automatic two speed transmission driving each shoe. A planetary gear set may be a compact way of getting a high gear ratio, but it will not change speed as the terrain gets harder to drive over such as up an incline. Having a two speed automatic helps having low speed and higher speed when on terrain with little resistance. Another option is to use a train controller, but not everyone has a train controller for their PF technic sets to set one of eight speeds per channel. It is also hard to remotely choose the power level that each track needs. Seems to me that a cvt would be the best solution for a gearbox per shoe to drive this model. The benefit being that having an automatic variable transmission between an arbitrary low speed and a high speed enables the excavator to choose for itself the torque that it needs at any given time to get over an obstacle. Hopefully without stalling.

How does a cvt transmission work? Good question. Let's start with what it is at a high level.

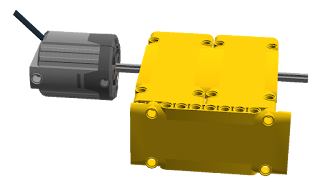

This is a motor going into a box that produces an output drive axle. The input goes in at one rotation speed and the output may be a different output speed in either direction or no speed at all.

If we want to make a CVT we need to look at what the rules are for this box. A CVT is defined by its lowest and highest gear ratios. In other words the output speed will be in the range of the lowest to highest ratios of the input speed. For example let's say a sample CVT has a lowest ratio of 1:4 and a highest ratio of 1:1. This means that a rotation speed of 100rpm produces an output range of 25 to 100 rpm. The speed of the output varies based on the torque required to drive the output shaft or by a manual control(as in a car with CVT). In this case we want the output speed to be automatically chosen based on the resistance encountered.

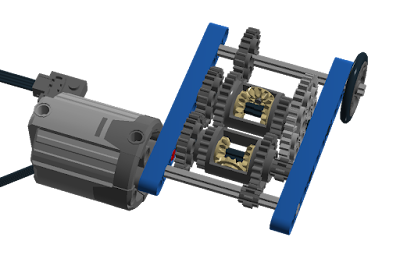

You may have encountered some flavour of this Lego CVT:

Let's break down what is happening here. The motor drives a small 8 tooth gear that drives the first open differential. The job of an open differential is to transmit power equally to each output shaft. The tan coloured gears in the middle see to this.

The output on the left of the first open differential is a large 24 tooth gear that drives another 24 tooth gear that finally drives the second open differential. Since both gears are the same size it is a 1:1 ratio on that side.

The output on the right of the first open differential is a small 8 tooth gear that drives a much larger 40 tooth gear which in turn drives the second differential. The ratio in this case is 8:40 or 1:5.

Finally the second open differential combines the two drive shafts into one output by averaging the input speeds (or so we hope). It is important that the differentials are of the open type so that power can be instantly transferred back through the drive shafts.

Imagine that there is no friction on the wheel and the gears can all spin freely. In this case we would have both the high and low ratios in the same amount and at the same time. The second differential would combine the two. In the example of 100rpm this would be an addition of 20 and 100 (120) then divided by 2 equaling 60rpm. If the vehicle were moving down a hill it could get up to 100 rpm at its maximum without overpowering the motor. If it were going up a hill then we would expect the lowest speed to be 20rpm. On a small incline this may happen, but there is a problem in practice. What happens when the driven wheel is locked and cannot spin? For the implementation above it is that the net output power is zero. Why is that? Shouldn't it be 20?

This implementation permits all gears to spin in any direction freely so if the output shaft is at zero speed then the power has to go to the other shaft. Since neither shaft entering the second differential have any rotational bias, both shafts fight one another until the one with the least resistance loses and is rotated backwards. Once this happens all power to the ouput shaft is gone except for the amount required to overcome the minimal resistance in the entire system. One solution is to put fly-wheels on the two shafts so that they maintain momentum, but this is not a fix as it still only woks while the output shaft can rotate.

For my purposes this is not sufficient. I can't have the output power become zero if the driven wheel is stalled. In this case I need even more torque with a guaranteed minimum output speed just like a pneumatic drive has a guaranteed amount of output power even at stall.

If we could limit the stall behavior to not permit the counter-rotation then we would have better results. If we use some form of friction wheel or even a limited slip differential there would still be some upper bound that would overcome the internal friction. If we dictated that the gear reduced drive shafts were driven in only one direction we would still have the benefit of the open differentials, but in slightly more limited output.

Looking at the stall case we want power out to equal the lowest ratio side. In other words the output needs to be low gear ratio rotation speed minus no input from the high ratio side. If the lowest gear ratio side wire limited to only rotate in the direction driven then the driven wheel would be guaranteed this lowest rotation speed in the case where it were attempted to be stalled. This does mean that if the motor can overpower a gear or axle in the transmission that something will skip or worse, break. I'm willing to take that chance, but for those not, just add as many clutch gears in parallel as desired on the output of the motor (the Lego BWE uses two on its XL motor).

Here is the same transmission with the low gearing converted to a one-direction low gearing.

Here it is again with both gearing sides converted, support structures removed and coloured for easier viewing.

Power from the motor turns the 16 tooth gear that drives the pink differential that drives a grey shaft and a black shaft. The grey shaft drives the yellow gear set for roughly a 1:5 ratio. The black shaft drives the green gear set for a ratio of 1:13. The two gear sets recombine in the purple differential and outputs to the blue 16 tooth gears.The output power equals the motor's output power at all times though the speed varies within the given ratios. In practice the whole system has a problem with using the low gear side even if the motor could drive the high side exclusively because the low side is easier to drive. A simple solution to this is to add a small rotational resistance to the low ratio gearset(green) before it enters the purple differential. The resistance needs to be equal to the gear resistance of running the high side(yellow gears) so that the green side is not used unless it is truly needed because the motor can not drive the high side.

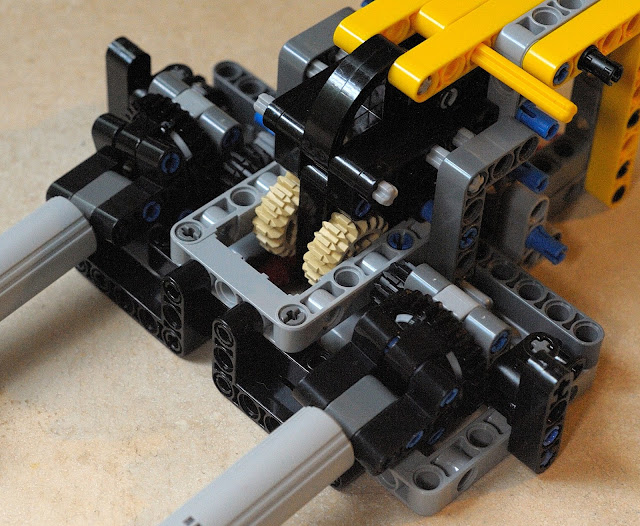

I have built several gear boxes to test this and it does work as desired, but doesn't look like it will fit in an excavator shoe. The next challenge is reshaping it to fit within the dimensions of the MOC's shoe: mostly 5 studs wide, 8 studs tall for the frame not including rollers/sprockets. This means that no gears should protrude from these dimensions at all.

This is getting closer. Now I still have to figure out what I'm going to do about the sprocket.

How does a cvt transmission work? Good question. Let's start with what it is at a high level.

This is a motor going into a box that produces an output drive axle. The input goes in at one rotation speed and the output may be a different output speed in either direction or no speed at all.

If we want to make a CVT we need to look at what the rules are for this box. A CVT is defined by its lowest and highest gear ratios. In other words the output speed will be in the range of the lowest to highest ratios of the input speed. For example let's say a sample CVT has a lowest ratio of 1:4 and a highest ratio of 1:1. This means that a rotation speed of 100rpm produces an output range of 25 to 100 rpm. The speed of the output varies based on the torque required to drive the output shaft or by a manual control(as in a car with CVT). In this case we want the output speed to be automatically chosen based on the resistance encountered.

You may have encountered some flavour of this Lego CVT:

Let's break down what is happening here. The motor drives a small 8 tooth gear that drives the first open differential. The job of an open differential is to transmit power equally to each output shaft. The tan coloured gears in the middle see to this.

The output on the left of the first open differential is a large 24 tooth gear that drives another 24 tooth gear that finally drives the second open differential. Since both gears are the same size it is a 1:1 ratio on that side.

The output on the right of the first open differential is a small 8 tooth gear that drives a much larger 40 tooth gear which in turn drives the second differential. The ratio in this case is 8:40 or 1:5.

Finally the second open differential combines the two drive shafts into one output by averaging the input speeds (or so we hope). It is important that the differentials are of the open type so that power can be instantly transferred back through the drive shafts.

Imagine that there is no friction on the wheel and the gears can all spin freely. In this case we would have both the high and low ratios in the same amount and at the same time. The second differential would combine the two. In the example of 100rpm this would be an addition of 20 and 100 (120) then divided by 2 equaling 60rpm. If the vehicle were moving down a hill it could get up to 100 rpm at its maximum without overpowering the motor. If it were going up a hill then we would expect the lowest speed to be 20rpm. On a small incline this may happen, but there is a problem in practice. What happens when the driven wheel is locked and cannot spin? For the implementation above it is that the net output power is zero. Why is that? Shouldn't it be 20?

This implementation permits all gears to spin in any direction freely so if the output shaft is at zero speed then the power has to go to the other shaft. Since neither shaft entering the second differential have any rotational bias, both shafts fight one another until the one with the least resistance loses and is rotated backwards. Once this happens all power to the ouput shaft is gone except for the amount required to overcome the minimal resistance in the entire system. One solution is to put fly-wheels on the two shafts so that they maintain momentum, but this is not a fix as it still only woks while the output shaft can rotate.

For my purposes this is not sufficient. I can't have the output power become zero if the driven wheel is stalled. In this case I need even more torque with a guaranteed minimum output speed just like a pneumatic drive has a guaranteed amount of output power even at stall.

If we could limit the stall behavior to not permit the counter-rotation then we would have better results. If we use some form of friction wheel or even a limited slip differential there would still be some upper bound that would overcome the internal friction. If we dictated that the gear reduced drive shafts were driven in only one direction we would still have the benefit of the open differentials, but in slightly more limited output.

Looking at the stall case we want power out to equal the lowest ratio side. In other words the output needs to be low gear ratio rotation speed minus no input from the high ratio side. If the lowest gear ratio side wire limited to only rotate in the direction driven then the driven wheel would be guaranteed this lowest rotation speed in the case where it were attempted to be stalled. This does mean that if the motor can overpower a gear or axle in the transmission that something will skip or worse, break. I'm willing to take that chance, but for those not, just add as many clutch gears in parallel as desired on the output of the motor (the Lego BWE uses two on its XL motor).

Here is the same transmission with the low gearing converted to a one-direction low gearing.

Here it is again with both gearing sides converted, support structures removed and coloured for easier viewing.

Power from the motor turns the 16 tooth gear that drives the pink differential that drives a grey shaft and a black shaft. The grey shaft drives the yellow gear set for roughly a 1:5 ratio. The black shaft drives the green gear set for a ratio of 1:13. The two gear sets recombine in the purple differential and outputs to the blue 16 tooth gears.The output power equals the motor's output power at all times though the speed varies within the given ratios. In practice the whole system has a problem with using the low gear side even if the motor could drive the high side exclusively because the low side is easier to drive. A simple solution to this is to add a small rotational resistance to the low ratio gearset(green) before it enters the purple differential. The resistance needs to be equal to the gear resistance of running the high side(yellow gears) so that the green side is not used unless it is truly needed because the motor can not drive the high side.

I have built several gear boxes to test this and it does work as desired, but doesn't look like it will fit in an excavator shoe. The next challenge is reshaping it to fit within the dimensions of the MOC's shoe: mostly 5 studs wide, 8 studs tall for the frame not including rollers/sprockets. This means that no gears should protrude from these dimensions at all.

This is getting closer. Now I still have to figure out what I'm going to do about the sprocket.

Thursday, July 20, 2017

EC750E brain dump

I'm still waiting for parts, but some have come in. The double rims with studs as a sprocket does fit well in size, but does not drive the track at all. I'll either have to use spur gears elsewhere to drive the track or use something else for a spur gear.

While I've been waiting for parts for the shoes I thought about tackling some of the other problems.

One of them is the drive system. The Volvo EC750E has a two speed automatic gearbox per shoe. This permits both high and low speed. It would be nice to have this in the model so what are the parts required. Two motive sources(maybe XL motors), two transmissions(one per shoe), one battery box, one receiver. Due to the rotation of the body I'm expecting to need to locate all of the parts below the body such as in the X-frame and shoes. I find the automatic transmissions done in Lego to be a bit clunky, but they work. I've also looked into Lego CVT transmissions, but they have a big problem in that if rotation is entirely stopped on the output shaft the internal gears battle amongst each other to counter-rotate and torque to the output shaft is lost. This will not do. I'll have to revisit the CVT concept as I would love to have a smooth final drive ratio like say 1:20 to 1:4 depending on the friction of the environment driven on.

While I've been waiting for parts for the shoes I thought about tackling some of the other problems.

One of them is the drive system. The Volvo EC750E has a two speed automatic gearbox per shoe. This permits both high and low speed. It would be nice to have this in the model so what are the parts required. Two motive sources(maybe XL motors), two transmissions(one per shoe), one battery box, one receiver. Due to the rotation of the body I'm expecting to need to locate all of the parts below the body such as in the X-frame and shoes. I find the automatic transmissions done in Lego to be a bit clunky, but they work. I've also looked into Lego CVT transmissions, but they have a big problem in that if rotation is entirely stopped on the output shaft the internal gears battle amongst each other to counter-rotate and torque to the output shaft is lost. This will not do. I'll have to revisit the CVT concept as I would love to have a smooth final drive ratio like say 1:20 to 1:4 depending on the friction of the environment driven on.

The large technic turntable is roughly 7 studs wide, but I need something closer to 11 or 12 studs wide for the model. I've been playing around with all sorts of ideas about how to accomplish this like support rollers front and back, but none have stood up to tests very well. I'm not leaning towards a hybrid technic/system brick solution wherein the force on the turntable will be distributed across a 12L brick built ring and an internal turntable. First try at this resulted in parts pulling themselves apart because of an inability to anchor the weight of the body to the X frame. What I've come to as a solution in to have two stacked central large turntables so that the one on the bottom can pull up on the X frame from underneath and the one on top can push down while sharing the load with the brick built 12L ring that acts like a fixed washer/bearing. There is enough space to have an 8 tooth spur gear driving a type 2 large turntable on top. A type 3 turntable can be used on the bottom for added rigidity over the type 2.

Then there is the problem of the boom drive and possibly the cylinders tearing themselves apart under too high a load. Just for fun I put a 3 pound jar (roughly 1.3Kg) on the front boom of my BWE standard model and supported the central frame with one hand while operating the gear to actuate the cylinders with the other. They held on just fine so I'll move ahead with my own paired design cautiously and do another weight test after the current body revision is built.

Lots more learning about the model and possible Lego implementation has been going on, but I'm a bit stalled while trying to solve too many problems at the same time. Maybe I'll tackle the CVT first.

Thursday, July 13, 2017

EC750E boom drive part 3

Fitting the new narrower cylinder drive still has overlap problems. At 12 stud width it is still too wide to fit in the maximum width that the model can handle before being way out of spec.

Looking at this photo it is clear to see how the turntable overlaps the space for the cab.

Time to rebuild the boom drive yet again using the half width gears, giving up a little on final drive ratio, and using an even thinner support frame to try and achieve a 9 stud width so that it fits within the space that the model requires on the frame.

In the photo above the new build is on the right side. It is one full stud width narrower. Note the single half beam between the tan coloured 12 tooth gears. This is the same gearing principles as the prior builds, but lower gear ratio to permit a tighter transfer box. This worked out better for framing strength. Bracing is added in the middle of the gears to always have a support on each side of the gears even in the middle of the transfer box. The space for the boom is now 6 studs, not the 7 that I had originally built so the boom will require a redesign. I may also reconsider the support structure for this boom drive as it would work better structurally if it more closely mimicked the real Volvo body frame:

Looking at this photo it is clear to see how the turntable overlaps the space for the cab.

Time to rebuild the boom drive yet again using the half width gears, giving up a little on final drive ratio, and using an even thinner support frame to try and achieve a 9 stud width so that it fits within the space that the model requires on the frame.

In the photo above the new build is on the right side. It is one full stud width narrower. Note the single half beam between the tan coloured 12 tooth gears. This is the same gearing principles as the prior builds, but lower gear ratio to permit a tighter transfer box. This worked out better for framing strength. Bracing is added in the middle of the gears to always have a support on each side of the gears even in the middle of the transfer box. The space for the boom is now 6 studs, not the 7 that I had originally built so the boom will require a redesign. I may also reconsider the support structure for this boom drive as it would work better structurally if it more closely mimicked the real Volvo body frame:

Wednesday, July 12, 2017

EC750E boom drive part 2

I created a very basic frame for sizing the width and length of the excavator body based on the calculated Lego dimensions. Comparing the frame to the current boom drive the current

width of 13 studs is clearly not going to work. 27(26.3 rounded up) studs is the

max width of the cab so ideally the cylinders are 9 to 11 studs wide.

Here is the same drive principle, but only 11 studs wide.

Looks good, but there is a problem here. The base of the cylinders is the small turntable and the gear teeth stick out of the 3x3 space into a 4x4 space making the 11 width design take 12 stud width space at best and 13 stud width if counting full width beams. Now we need an even more narrow design, but will it be possible to drive the turntables without resorting to twisty axles?

Looks good, but there is a problem here. The base of the cylinders is the small turntable and the gear teeth stick out of the 3x3 space into a 4x4 space making the 11 width design take 12 stud width space at best and 13 stud width if counting full width beams. Now we need an even more narrow design, but will it be possible to drive the turntables without resorting to twisty axles?

Tuesday, July 11, 2017

EC750E boom drive cylinder

Driving the cylinders that lift the main boom requires taking many parameters into consideration. The bucket, arm(3.55), and boom(7.7) fully extended have a reach of 92 studs. If the longest arm were used it would be 100 studs. The pivot point used by the cylinder is 6 studs away from the base of the boom. The cylinder is clearly at a mechanical disadvantage. If the pivot were at 46 studs then the weight of the bucket/arm/boom would be the only force down on the cylinder, but it is at 6. This is a mechanical disadvantage of 7.666. Given that the bucket/arm/boom may weigh up to 1Kg fully laden, the cylinders have a lot of compression force to deal with. Any give in the design of the cylinder drive is going to show quickly.

This joint fails because the 13L dark grey liftarms that sandwich the light grey 3L cross block used for the drive shaft gears is not locked in place. As the torque goes up the beams pull apart and the whole mechanism fails.

The chassis needs to be able to handle the weight down and the gear boxing needs to arrest the dimensional forces of each gear. More on the chassis later. Two gears in the same plane acting on one another will try to push the other away in the one plane. When two gears are in perpendicular planes the forces push the gears apart in all three dimensions. The simplest way to handle perpendicular gears is to use a box on each perpendicular connection. Having more that one perpendicular connection on a single gear can be tricky as two boxes need to interact together adding to the forces that are trying to pull them apart. Ideally the two perpendicular gear connections are split into two gear sets connected by a driveshaft. This permits more room for structural components even if complexity goes up a bit.

This setup does the above.

This joint fails because the 13L dark grey liftarms that sandwich the light grey 3L cross block used for the drive shaft gears is not locked in place. As the torque goes up the beams pull apart and the whole mechanism fails.

The chassis needs to be able to handle the weight down and the gear boxing needs to arrest the dimensional forces of each gear. More on the chassis later. Two gears in the same plane acting on one another will try to push the other away in the one plane. When two gears are in perpendicular planes the forces push the gears apart in all three dimensions. The simplest way to handle perpendicular gears is to use a box on each perpendicular connection. Having more that one perpendicular connection on a single gear can be tricky as two boxes need to interact together adding to the forces that are trying to pull them apart. Ideally the two perpendicular gear connections are split into two gear sets connected by a driveshaft. This permits more room for structural components even if complexity goes up a bit.

This setup does the above.

Monday, July 10, 2017

EC750E shoe free spinning wheel

A different track related question is which wheel looks better for the front free spinning wheel/sprocket?

I'm inclining towards the wheel in the middle as it is 3 studs wide whereas the tire is 4 and the wheel on the right is 5.

I'm inclining towards the wheel in the middle as it is 3 studs wide whereas the tire is 4 and the wheel on the right is 5.

EC750E track drive update

The first track drive design had some problems. Notably the carrier for the planetary gear set was locked to the ring gear instead of the sun gear. Even better would be if it could counter rotate at a fixed rate to increase the output gear ratio. This is done below. The "drive sprocket" is now a paired ring wheel which also solves the problem of how to take power off the drive wheel to drive a proper sprocket since the drive wheel is not a proper sprocket.

In the picture above, the pink half of a turntable will be removed to permit a more narrow build. Power comes in from the red axle. The blue carriage on the turntable side will spin based on the planetary gear set of the turntable. This will increase the final drive ratio of the ring wheel driving the track by counter rotating the carriage of the drive wheel gear set. Finally the paired drive wheel will continue to transfer power along the green drive axle and power a sprocket somewhere along the track. At least I hope so. Once the parts that I have ordered through bricklink come in, I'll make this for real and test it out.

In the picture above, the pink half of a turntable will be removed to permit a more narrow build. Power comes in from the red axle. The blue carriage on the turntable side will spin based on the planetary gear set of the turntable. This will increase the final drive ratio of the ring wheel driving the track by counter rotating the carriage of the drive wheel gear set. Finally the paired drive wheel will continue to transfer power along the green drive axle and power a sprocket somewhere along the track. At least I hope so. Once the parts that I have ordered through bricklink come in, I'll make this for real and test it out.

Thursday, July 6, 2017

EC750E track drive sprocket

The dimensions in studs for each shoe of the excavator is 46 studs long by 8.3(maybe 8 or 9) studs wide by 10.5 studs tall. That means the total shoe structure should be 45 studs long and 10 studs tall with the track making up the remaining space above, below, front, and back.

From the discussion on the Eurobricks forum, there is interest in what sprockets will be used. I have not been able to find dimensions on the diameter of the main drive and idler sprockets at the front and back of the tracks. From various diagrams and photos I'm guessing these to be about 8 studs. The stock sprockets are roughly 3 and 5 studs in diameter; clearly too small. I'm currently considering the wheel from the old mining vehicle for its ability to be used as a planetary gear set and the large turntable for its almost 8 stud size. Probably something like this:

The only problem here is that while the teeth on the type 3 large turntable work on the track because of the larger spacing between teeth(vs type 2 pictured which doesn't), it doesn't drive the track acceptably well when I try it in practice. Probably the driven turntable will in turn drive some other gear mechanism going to a small 3 stud sprocket to drive the track at the same rate. At least that is what I'm hoping since I like the size of the large turntable.

Subscribe to:

Posts (Atom)